Instalaciones y tecnología

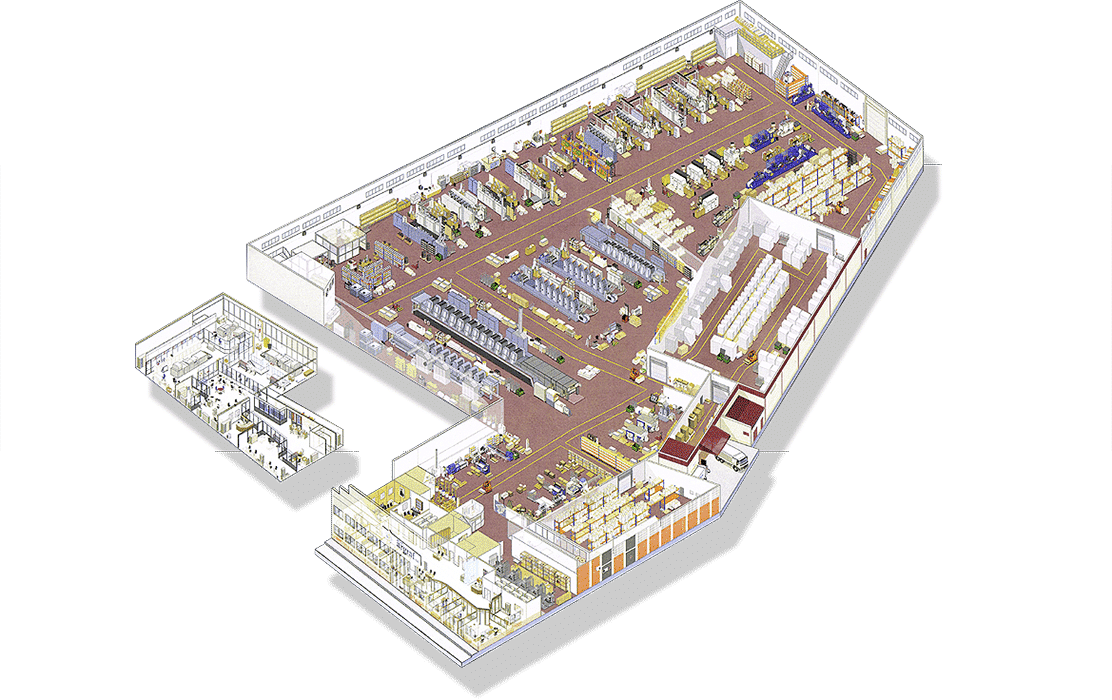

El Grupo Argraf cuenta con 10.000 metros cuadrados de instalaciones en la localidad alavesa de Oyón, a 3 kilómetros de Logroño y en pleno corazón de una de las regiones vitivinícolas más importantes del mundo, La Rioja.

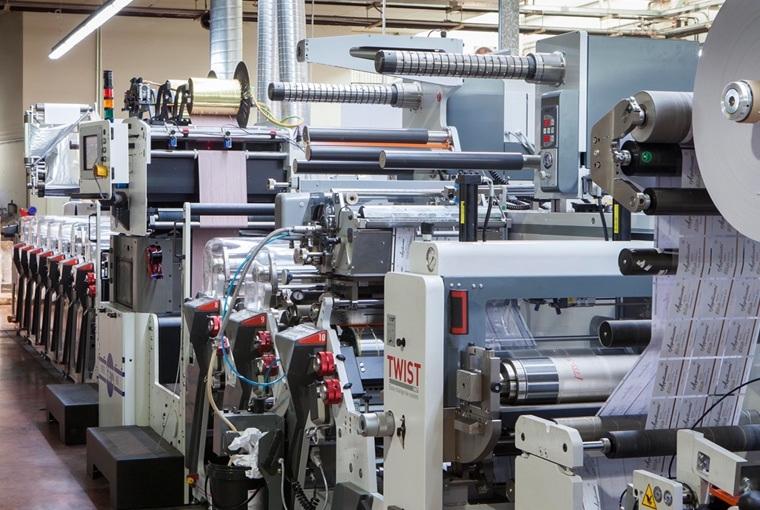

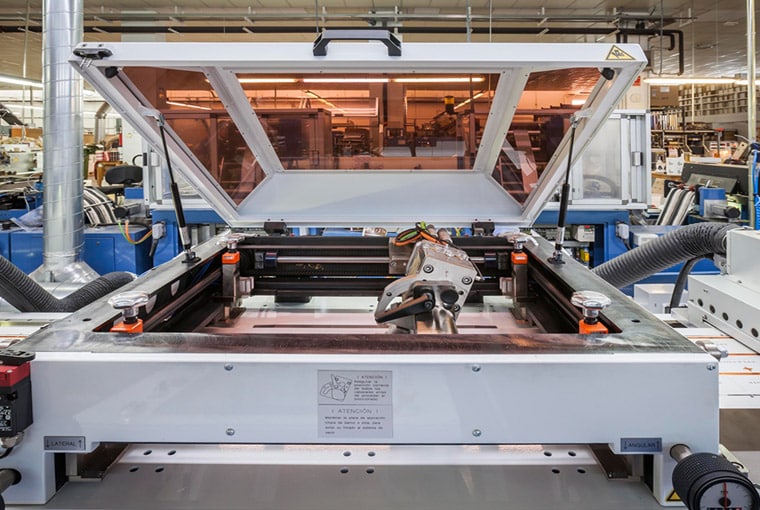

Distribuidas en varias naves, nuestras instalaciones albergan 20 máquinas de impresión con 102 cuerpos, y 18 máquinas de estampación y acabado, operadas por una plantilla de técnicos compuesta por 80 personas. Además, el complejo contiene importantes áreas de almacenamiento y depósito, zona de carga, oficinas administrativas, áreas de diseño, etcétera.

En total, el Grupo Argraf tiene a más de 140 personas entre su personal, la mayoría expertos de alta cualificación en sus respectivas áreas de conocimiento. Por otra parte, la amplitud de nuestras instalaciones nos permite afrontar la cada vez mayor demanda de nuestros servicios.